Autonomous robots are going to play a crucial role in the new era of AI driven manufacturing processes. Currently, robotics systems required a significant amount of human intervention from program path generation to quality inspection and process monitoring, resulting in very inefficient and expensive automated manufacturing processes. The first phase of the project focuses on the development and construction of a novel Autonomous Robotics system for part inspection and part assembling.

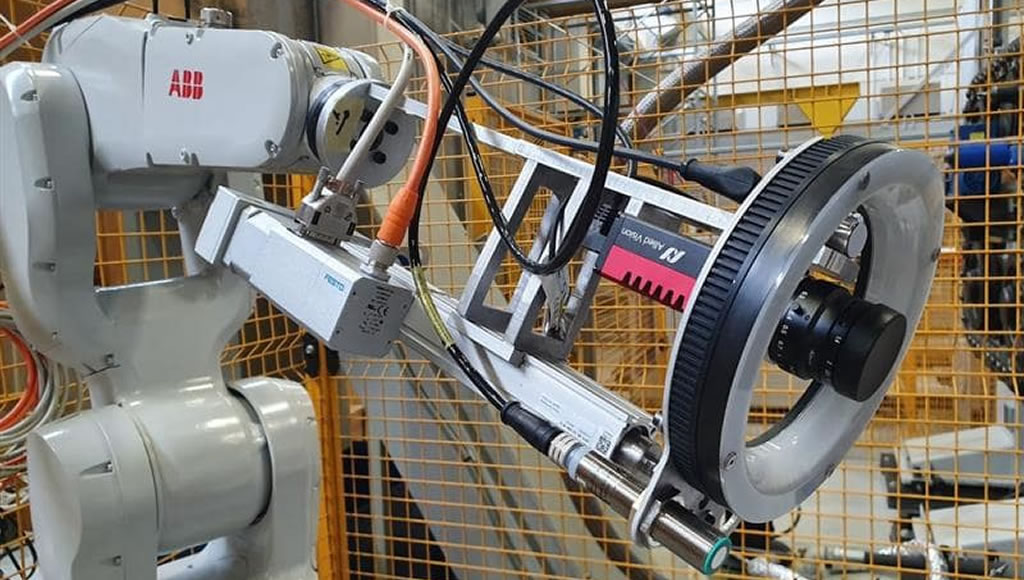

This novel Autonomous Robotics system called "FRANK", it leverages state of the art in machine learning, deep learning, vision sensors (camera, profilometer) and programmable lights, to empower industrial robots with a proprietary synthetic brain (AI driven control) and end-effector (Camera, profilometer, programmable light), making FRANK fully autonomous in the generation of part-programs, inspection/monitoring and execution of part assembling and quality verification.

FRANK's synthetic brain can be trained via a set of high quality images of rivets, fasteners and more. The high resolution images required to train FRANK are captured by leveraging FRANK's advanced vision end-effector composed of camera, profilometer and programmable lights. FRANK will significantly reshape important manufacturing tasks such assembling and part inspection.